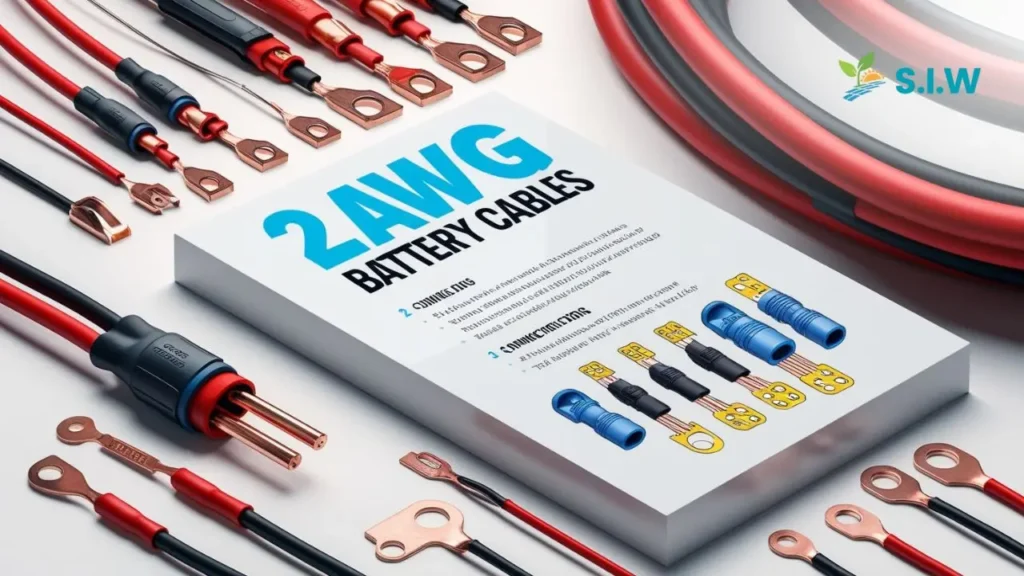

When dealing with high-power electrical systems, the 2 AWG battery cable is a critical component that ensures optimal performance, safety, and reliability. Whether you’re working on automotive, marine, or industrial applications, understanding the specific qualities of a 2 AWG battery cable and its use is essential to making informed decisions. In this comprehensive guide, we will explore everything you need to know about 2 AWG battery cables—from their construction to their applications and technical specifications.

What Is a 2 AWG Battery Cable?

A 2 AWG (American Wire Gauge) battery cable is a thick, high-capacity cable used to transmit electrical power from the battery to various components of a system. The AWG system refers to a standardized wire gauge system in the United States that measures the diameter of the wire. In this case, 2 AWG wires have a diameter of approximately 0.2576 inches (6.544 mm). The lower the gauge number, the thicker the cable, making 2 AWG one of the more robust choices for high-power systems.

Construction of a 2 AWG Battery Cable

A typical 2 AWG battery cable consists of copper conductors surrounded by high-quality insulation. Copper is the preferred material due to its excellent electrical conductivity and flexibility, which is crucial for tight spaces or installations requiring frequent movement.

- Stranded copper wire: The copper conductors in a 2 AWG cable are typically made up of multiple strands, which provides better flexibility than solid core wires. Stranded conductors are more resistant to breaking under stress or repeated bending, which is why they’re favored in automotive and marine applications.

- Insulation material: The insulation surrounding the conductor is commonly made from durable materials like PVC (Polyvinyl Chloride) or XLPE (Cross-linked Polyethylene). These materials are selected for their ability to withstand high temperatures, abrasion, and chemical exposure, making the cables suitable for harsh environments.

- Heat resistance: Most 2 AWG battery cables are rated to handle operating temperatures up to 105°C (221°F), ensuring safe operation even in extreme conditions.

Why Use a 2 AWG Battery Cable?

The primary reason to choose a 2 AWG battery cable is its ability to handle high current loads with minimal voltage drop. In high-power applications such as automotive electrical systems, marine batteries, solar installations, and industrial machinery, maintaining a stable voltage is crucial for performance and safety. The 2 AWG wire’s thicker gauge reduces electrical resistance, thereby minimizing power loss over longer distances.

Key Benefits of 2 AWG Battery Cables:

- High current capacity: 2 AWG cables can handle higher amperage than thinner cables. Typically, they can manage 95 to 150 amps, depending on the length of the run and environmental conditions.

- Low voltage drop: For large-scale applications requiring long cable runs, 2 AWG offers lower resistance, reducing voltage drop and ensuring consistent power delivery to critical systems.

- Durability and flexibility: The stranded design makes 2 AWG cables not only durable but also flexible, allowing easy installation in confined spaces.

Technical Specifications of 2 AWG Battery Cables

Understanding the technical aspects of 2 AWG battery cables can help you choose the right option for your specific application. Below are the most critical specifications:

- Nominal OD (Outside Diameter): Approx. 0.426 inches (10.82 mm) depending on the insulation type used.

- Resistance per 1,000 feet: Approx. 0.156 ohms.

- Max Ampacity: Typically between 130 and 150 amps for short runs in ambient conditions up to 30°C (86°F).

- Insulation Thickness: Depending on the cable type, insulation is typically around 0.045 inches (1.14 mm) thick.

- Conductor Material: Usually 100% copper for best performance. Some lower-grade options use aluminum but are less conductive.

- Weight: 2 AWG copper cables weigh approximately 145 lbs per 1,000 feet, which is essential to keep in mind when planning installations for weight-sensitive applications such as aviation or motorsports.

Applications of 2 AWG Battery Cables

Due to their robustness and high current-carrying capabilities, 2 AWG battery cables are commonly used in a wide variety of applications, including:

Automotive Applications

In the automotive industry, 2 AWG battery cables are frequently used to connect the starter motor to the battery or the alternator. High-performance vehicles, trucks, and large SUVs, which have greater electrical demands, rely on these cables for seamless power transmission.

Marine Applications

In marine environments, 2 AWG cables are essential for connecting boat batteries to critical electrical systems. The harsh conditions—such as exposure to saltwater, vibrations, and extreme weather—require cables that can withstand corrosion, which is why marine-grade, tinned copper conductors are often used for added longevity.

Solar and Renewable Energy Systems

In solar power installations, especially in off-grid setups, 2 AWG battery cables are used to connect solar batteries, inverters, and charge controllers. The low voltage drop and high ampacity ensure that the energy generated is efficiently transferred and stored, making it a popular choice in this growing field.

Industrial Equipment

In heavy-duty machinery, such as construction equipment or manufacturing plants, 2 AWG cables are used to power motors, welding machines, and other high-power tools. The cables’ durability and heat resistance make them suitable for demanding environments.

Inverter Systems and RVs

2 AWG battery cables are also widely used in recreational vehicles (RVs) and inverter systems that need to manage large amounts of power. In these setups, the 2 AWG wire can easily handle the load required for appliances, lighting, and other electrical systems.

Choosing the Right 2 AWG Battery Cable for Your Application

Not all 2 AWG battery cables are created equal. It’s essential to select the right type based on your specific requirements. Here are the factors to consider when choosing a 2 AWG cable:

Insulation Type

- PVC: More affordable, suitable for general use in automotive and basic marine applications.

- XLPE: Higher heat resistance and chemical durability, ideal for harsh environments.

Marine Grade

If you’re using the cable in a marine environment, always opt for marine-grade cables with tinned copper strands. This offers extra protection against corrosion and extends the cable’s lifespan.

Length of the Cable Run

Longer runs introduce more resistance, which can lead to a voltage drop. Always calculate the required cable length and ensure that a 2 AWG cable meets the ampacity needs over the desired distance.

Installation and Maintenance Tips

Proper installation of 2 AWG battery cables is crucial for optimal performance and longevity. Follow these tips to ensure your cables perform at their best:

- Secure Connections: Always use high-quality lugs or connectors that fit tightly onto the battery terminals. Poor connections lead to higher resistance and heat buildup.

- Avoid Sharp Bends: While the stranded design of 2 AWG cables makes them flexible, sharp bends can still stress the conductors and insulation, leading to potential failure.

- Use Heat Shrink Tubing: For added protection and durability, use heat shrink tubing over the connectors to prevent moisture ingress and mechanical wear.

- Regular Inspection: Periodically inspect the cables for signs of wear, such as cuts in the insulation, corrosion at the connectors, or excessive heat at the terminals.

Conclusion

A 2 AWG battery cable is an indispensable tool in high-current applications. Its thick gauge, low resistance, and high current capacity make it the go-to choice for powering everything from heavy-duty industrial machines to off-grid solar systems. By understanding the construction, specifications, and applications of 2 AWG battery cables, you can ensure you’re using the right equipment for your power needs. Always invest in high-quality, durable materials to guarantee optimal performance, safety, and longevity.

By paying close attention to the factors mentioned above and choosing the right cable for your specific needs, you can ensure that your system remains efficient and reliable for years to come.